This project by DLSU students hopes to turn food waste in cafeterias to biogas for cooking | ABS-CBN

Welcome, Kapamilya! We use cookies to improve your browsing experience. Continuing to use this site means you agree to our use of cookies. Tell me more!

This project by DLSU students hopes to turn food waste in cafeterias to biogas for cooking

This project by DLSU students hopes to turn food waste in cafeterias to biogas for cooking

Josiah Eleazar Antonio,

ABS-CBN News

Published Nov 30, 2024 08:00 AM PHT

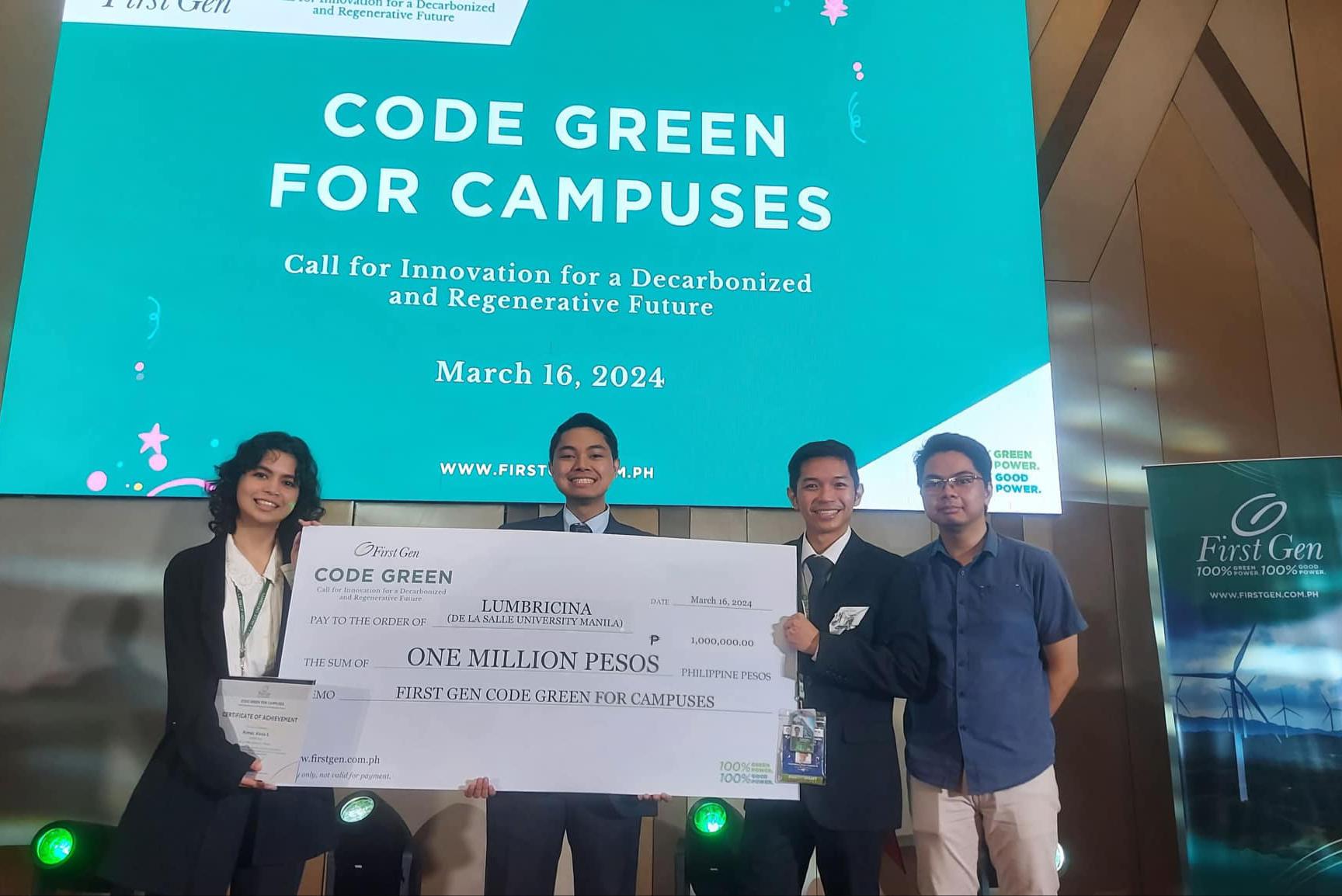

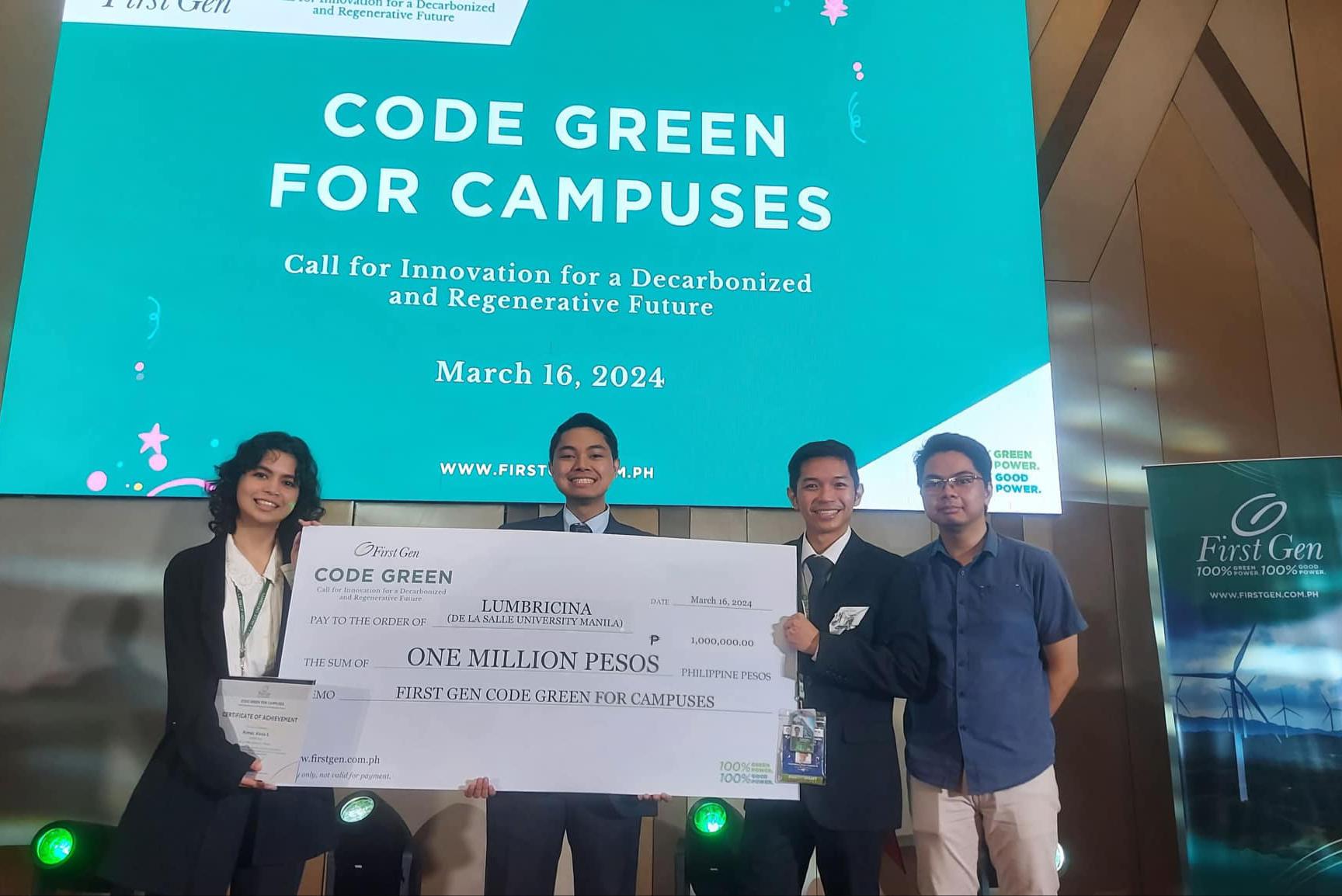

De La Salle University Alexia Roman, Fernando Magallanes, and Ralph Stephen Saavedra. Photo courtesy of First Gen Corp

De La Salle University Alexia Roman, Fernando Magallanes, and Ralph Stephen Saavedra. Photo courtesy of First Gen Corp

De La Salle University Alexia Roman, Fernando Magallanes, and Ralph Stephen Saavedra. Photo courtesy of First Gen Corp

De La Salle University Alexia Roman, Fernando Magallanes, and Ralph Stephen Saavedra. Photo courtesy of First Gen Corp MANILA — A project by three De La Salle University (DLSU) - Manila students hopes to utilize food waste in cafeterias to reduce the LPG consumption costs.

MANILA — A project by three De La Salle University (DLSU) - Manila students hopes to utilize food waste in cafeterias to reduce the LPG consumption costs.

Named as Chester, the technology is a compact anaerobic digester system food designed to convert kitchen food waste into biogas that can be used for cooking.

Named as Chester, the technology is a compact anaerobic digester system food designed to convert kitchen food waste into biogas that can be used for cooking.

The project, led by organizational communication student Alexia Roman, manufacturing engineering and management major Fernando Magallanes, and applied financial economics student Ralph Stephen Saavedra, won the P1-million grant from a national contest by First Gen Corporation, which aims to spotlight innovative strategies for reducing carbon emissions within educational institutions.

The project, led by organizational communication student Alexia Roman, manufacturing engineering and management major Fernando Magallanes, and applied financial economics student Ralph Stephen Saavedra, won the P1-million grant from a national contest by First Gen Corporation, which aims to spotlight innovative strategies for reducing carbon emissions within educational institutions.

With its ongoing development in DLSU's Laguna campus, Saavedra said that they are aiming for its commercial use to help the environment and the economy.

With its ongoing development in DLSU's Laguna campus, Saavedra said that they are aiming for its commercial use to help the environment and the economy.

ADVERTISEMENT

"Upon seeing the potential environmental and economic benefits this project would be providing, we ventured out into actually developing it into a viable business, wherein the grant we acquired from First Gen is really useful funding for us to do an even more thorough and proper prototyping of the design we had proposed, particularly within the Laguna campus," Saavedra told ABS-CBN News.

"Upon seeing the potential environmental and economic benefits this project would be providing, we ventured out into actually developing it into a viable business, wherein the grant we acquired from First Gen is really useful funding for us to do an even more thorough and proper prototyping of the design we had proposed, particularly within the Laguna campus," Saavedra told ABS-CBN News.

"That would be the area where we would be conducting our tests and to make further tweaks or additions towards the project as we try to create a minimum viable product for commercialization," he added.

"That would be the area where we would be conducting our tests and to make further tweaks or additions towards the project as we try to create a minimum viable product for commercialization," he added.

WHAT CAN CHESTER DO?

Chester automates food waste processing and biogas production using prefabricated materials to ensure safety and efficiency, the study's abstract said.

Chester automates food waste processing and biogas production using prefabricated materials to ensure safety and efficiency, the study's abstract said.

Aside from biogas, Magallanes said that Chester will also produce fertilizer that can be used for urban farming.

Aside from biogas, Magallanes said that Chester will also produce fertilizer that can be used for urban farming.

"We're trying to harness the methanogenic process for the decomposing of biodegradables, particularly on food waste, utilizing the methane-loving bacteria, called methanogenic bacteria, methanogens rather. And the operations for the biogas mainly revolves on first sorting the waste to retrieve biodegradables, shredding it properly to granules," Magallanes said.

"We're trying to harness the methanogenic process for the decomposing of biodegradables, particularly on food waste, utilizing the methane-loving bacteria, called methanogenic bacteria, methanogens rather. And the operations for the biogas mainly revolves on first sorting the waste to retrieve biodegradables, shredding it properly to granules," Magallanes said.

"Then afterwards, it will proceed to a 14 days retention time for fermentation, and within that tank of fermentation, it will output biogas and another output of that will be compost that can be used as a soil amendment or fertilizer for urban farming," he added.

"Then afterwards, it will proceed to a 14 days retention time for fermentation, and within that tank of fermentation, it will output biogas and another output of that will be compost that can be used as a soil amendment or fertilizer for urban farming," he added.

Their study indicates that Chester could store up to 2,200 kilograms of organic waste, specifically food waste, to generate 264 kilograms of biogas after digestate curing — which is sufficient for 677 hours of continuous cooking on a small single-burner stove given a single batch of 2,200 kilograms of organic waste.

Their study indicates that Chester could store up to 2,200 kilograms of organic waste, specifically food waste, to generate 264 kilograms of biogas after digestate curing — which is sufficient for 677 hours of continuous cooking on a small single-burner stove given a single batch of 2,200 kilograms of organic waste.

It also "demonstrates the benefits of waste-to-energy technologies," and by redirecting roughly 88,320 kilograms of greenhouse gas emissions into usable biogas annually, the device would be able to offset roughly a total of 480,000 kilograms of biogas throughout its ten year useful life, it added.

It also "demonstrates the benefits of waste-to-energy technologies," and by redirecting roughly 88,320 kilograms of greenhouse gas emissions into usable biogas annually, the device would be able to offset roughly a total of 480,000 kilograms of biogas throughout its ten year useful life, it added.

"So depending on how you treat the process, if you have any additional agitators or heating process added up to the system that can add up to the speed or to the amount of biogas being retrieved from your food waste," Magallanes said.

"So depending on how you treat the process, if you have any additional agitators or heating process added up to the system that can add up to the speed or to the amount of biogas being retrieved from your food waste," Magallanes said.

The group aims to finish their first prototype by the end of February to March as they secure some measures to follow before they use the technology.

The group aims to finish their first prototype by the end of February to March as they secure some measures to follow before they use the technology.

HOW CHESTER CAN HELP THE ENVIRONMENT?

With their project, Saavedra hopes that they would put to use unsegregated and untreated organic waste that could reduce greenhouse gas emissions.

With their project, Saavedra hopes that they would put to use unsegregated and untreated organic waste that could reduce greenhouse gas emissions.

"What we often do not really address in this country is the hidden 'evil' or the hidden greenhouse gas emissions being emitted from unsegregated and untreated organic waste," Saavedra said.

"What we often do not really address in this country is the hidden 'evil' or the hidden greenhouse gas emissions being emitted from unsegregated and untreated organic waste," Saavedra said.

"And by doing so, via our project and others similar like it that are already in the Philippines, via anaerobic digestion plants or compact anaerobic digestion machines, we would be able to offset or rather reduce the amount of greenhouse gas emissions being generated by the country on aggregate from decomposing organic waste," he added.

"And by doing so, via our project and others similar like it that are already in the Philippines, via anaerobic digestion plants or compact anaerobic digestion machines, we would be able to offset or rather reduce the amount of greenhouse gas emissions being generated by the country on aggregate from decomposing organic waste," he added.

In the study's estimate, Chester can annually process up to roughly 40,000 kilograms of food waste, generating approximately 4,800 kilograms of biogas for the DLSU-Laguna campus.

In the study's estimate, Chester can annually process up to roughly 40,000 kilograms of food waste, generating approximately 4,800 kilograms of biogas for the DLSU-Laguna campus.

Saavedra added that their team is working on expanding their venture to hospitality establishments that deal with large amounts of wastes.

Saavedra added that their team is working on expanding their venture to hospitality establishments that deal with large amounts of wastes.

"One other thing that we would like to add is that we're currently working on having, on developing a minimum viable product so that we may be able to create a business out of this, wherein the business name is still Lumbricina, wherein our main provision would be through the production and maintenance of compact, unrepeated gestures to be used by commercial hospitality establishments, particularly those that deal and handle large amounts of food waste," he said.

"One other thing that we would like to add is that we're currently working on having, on developing a minimum viable product so that we may be able to create a business out of this, wherein the business name is still Lumbricina, wherein our main provision would be through the production and maintenance of compact, unrepeated gestures to be used by commercial hospitality establishments, particularly those that deal and handle large amounts of food waste," he said.

"And far into the future, we also plan to transition, or rather expand into the field of actual electricity generation via the process of industrial-scale unrepeated gesture plants."

"And far into the future, we also plan to transition, or rather expand into the field of actual electricity generation via the process of industrial-scale unrepeated gesture plants."

Roman said that people should be more active in discussing environmental issues and take action on how to save the planet.

Roman said that people should be more active in discussing environmental issues and take action on how to save the planet.

"It's also worth noting that DLSU prioritizes research and innovation. So implementing this compact biogas digester feels like a natural step or progression to that. So it's not just about managing waste, but also transforming it into something valuable or to a valuable resource," Roman said.

"It's also worth noting that DLSU prioritizes research and innovation. So implementing this compact biogas digester feels like a natural step or progression to that. So it's not just about managing waste, but also transforming it into something valuable or to a valuable resource," Roman said.

"Like for this example, it's the renewable energy for cooking and biofertilizer. So our goal would be also to more inspire and provide the Lasallians, like the students and faculty with hands-on opportunities to tackle real-world environmental challenges, which also reinforce our role as a sort of leader or catalyst in sustainable practices," she added.

"Like for this example, it's the renewable energy for cooking and biofertilizer. So our goal would be also to more inspire and provide the Lasallians, like the students and faculty with hands-on opportunities to tackle real-world environmental challenges, which also reinforce our role as a sort of leader or catalyst in sustainable practices," she added.

Read More:

DLSU

science

technology

environment

biogas

food waste

De La Salle University

First Gen Corporation

ADVERTISEMENT

ADVERTISEMENT